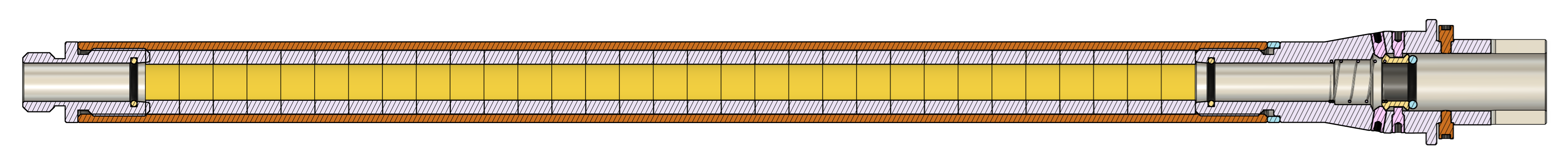

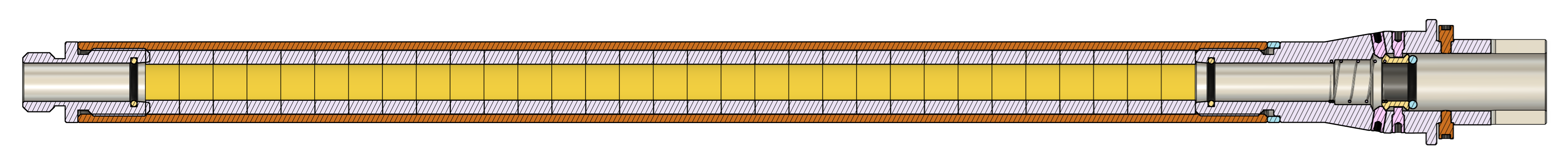

RETRO ARMS has developed two revolutionary designs for the standard AEG AR15. This is a custom outer barrel. The front and rear bases are made of EN-AW7075-T651 machined and anodized. The outer barrel is made of carbon pipe and is screwed to the base. (Some lots may be glued) The tip is an M14xP1.0 reverse thread, making it compatible with a variety of hiders and suppressors. The outer barrel diameter is 19mm, and various gas blocks can be attached to it. Be careful not to overtighten the mounting screws. ----------------------------------------------------------------------------------------------

This outer barrel has an inner barrel spacer inside, which is made of hard vibration-damping material for audio equipment. This makes it difficult for the impact vibrations of the gearbox and the air vibrations during firing to be transmitted to the inner barrel. The inner diameter of the vibration-damping material fits perfectly with the inner barrel, so even short inner barrels can be used without any problems. There are O-rings at the tip thread and base to prevent inner barrel rattle. If the O-ring is attached to the inner barrel itself, please remove it before use. ----------------------------------------------------------------------------------------------

This outer barrel has an inner barrel spacer inside, which is made of hard vibration-damping material for audio equipment. This makes it difficult for the impact vibrations of the gearbox and the air vibrations during firing to be transmitted to the inner barrel. The inner diameter of the vibration-damping material fits perfectly with the inner barrel, so even short inner barrels can be used without any problems. There are O-rings at the tip thread and base to prevent inner barrel rattle. If the O-ring is attached to the inner barrel itself, please remove it before use. ----------------------------------------------------------------------------------------------  The base is equipped with a unique chamber pressure tension adjustment and fixing function. From here on, we will explain how to assemble using the above part numbers.

The base is equipped with a unique chamber pressure tension adjustment and fixing function. From here on, we will explain how to assemble using the above part numbers.  Attach the three screws (9) to the base. These screws will engage with the receiver to prevent rotation.

Attach the three screws (9) to the base. These screws will engage with the receiver to prevent rotation.  Insert ⑤, ⑥, and ⑪ in that order. The wedge clamp (⑥) has a specific orientation, with the tapered surface indicated by the green arrow facing the muzzle. ----------------------------------------------------------------------------------------------

Insert ⑤, ⑥, and ⑪ in that order. The wedge clamp (⑥) has a specific orientation, with the tapered surface indicated by the green arrow facing the muzzle. ----------------------------------------------------------------------------------------------  The O-ring (11) is the company's CNC Hop-Up Chamber AR15 BASIC Or CNC Hop Up Chamber AR15 PRO dimensions are optimized, The distance from the gearbox contact surface to the tip of the chamber is 52.2 mm. If you use

The O-ring (11) is the company's CNC Hop-Up Chamber AR15 BASIC Or CNC Hop Up Chamber AR15 PRO dimensions are optimized, The distance from the gearbox contact surface to the tip of the chamber is 52.2 mm. If you use the

slightly shorter CNC Hop Up Chamber AR15 ULTRA, you will need a special wedge clamp .

When using a chamber made by another manufacturer, an additional O-ring may be required to match this dimension, so please prepare it separately. Slightly push the wedge clamp (⑥) so that the retaining screw (⑧) fits over the step indicated by the red arrow. Secure it in place by attaching the two retaining screws (8) on the left and right. ---------------------------------------------------------------------------------------------- After inserting the adjustment screws (7) in two places on the left and right, secure them with the barrel nut and assemble the chamber and gearbox set. Finally, tighten the screw ⑦ while checking the gap between the chamber and the gearbox. Once it is tightly attached, tighten it about half a turn to complete the adjustment. Apply a locking agent to this screw. The manufacturer says that it is okay to apply a force of up to 0.5 N·m to the adjustment screw (7). In fact, when applying 0.5N・m, the screw goes deep enough to penetrate the inner barrel. Furthermore, the threads will be damaged, so the chamber and gearbox must be properly attached. Once tension is applied, stop turning. ----------------------------------------------------------------------------------------------  Next, we will explain how to adjust the adjustment screw (7) if it is hidden by the barrel nut. As shown in the photo above, if the barrel nut is too long, the wrench will not fit.

Next, we will explain how to adjust the adjustment screw (7) if it is hidden by the barrel nut. As shown in the photo above, if the barrel nut is too long, the wrench will not fit.

In this case, temporarily assemble the outer barrel and chamber to the upper receiver without attaching the barrel nut.

In this case, temporarily assemble the outer barrel and chamber to the upper receiver without attaching the barrel nut.  Next, we will assemble the lower receiver, including the gearbox. Then, while pressing the outer barrel firmly against the upper receiver, turn the adjustment screw (7) little by little. Find a position where there is as little gap as possible between the "outer barrel" and the "upper receiver" (red arrow in the photo). Once you find it, turn the adjustment screw (7) half a turn to complete the adjustment. All that's left to do is assemble the handguard and secure the outer barrel with the barrel nut.

Next, we will assemble the lower receiver, including the gearbox. Then, while pressing the outer barrel firmly against the upper receiver, turn the adjustment screw (7) little by little. Find a position where there is as little gap as possible between the "outer barrel" and the "upper receiver" (red arrow in the photo). Once you find it, turn the adjustment screw (7) half a turn to complete the adjustment. All that's left to do is assemble the handguard and secure the outer barrel with the barrel nut.

*As this is an overseas product, there may be variations in the finish and color unevenness.

In addition, minor specification changes may occur without prior notice.

*Except in cases where the product is damaged or cannot be installed, causing serious problems with functionality.

Returns will not be accepted.

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_13_1024x1024.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_1024x1024.png?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_1_1024x1024.png?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_2_1024x1024.png?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_3_1024x1024.png?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_4_1024x1024.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_5_1024x1024.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_6_1024x1024.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_7_1024x1024.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_8_1024x1024.png?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_9_1024x1024.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_10_1024x1024.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_11_1024x1024.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_12_1024x1024.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_13_medium.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_medium.png?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_1_medium.png?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_2_medium.png?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_3_medium.png?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_4_medium.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_5_medium.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_6_medium.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_7_medium.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_8_medium.png?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_9_medium.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_10_medium.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_11_medium.jpg?v=1750662931)

![[RETRO ARMS] CNC 3K-carbon Outer Barrel AR15](http://rock-et.jp/cdn/shop/files/retro-arms-cnc-3k-carbon-outer-barrel-ar15_12_medium.jpg?v=1750662931)