No Products in the Cart

使い易く寒くても動作も問題なく良い銃です。

この度は当店をご利用いただき誠にありがとうございます😊

商品が無事にお手元に届き、安心いたしました。

寒い時期でも安定して動作してくれる点、気に入っていただけて嬉しいです☺️

これからもお客様に優れた製品と最高のサービスを提供できるよう努めてまいりますので、

また是非よろしくお願いいたします!

お客様のご利用を心よりお待ちしております。

A lovely replica of the american version of the french Protector of Jacques Edmond Turbiaux, even if he's made of HW polymer and aluminium alloyed, and non firing projectiles it's really a must to have for all lovers of old guns .

The more:

Full realistic mecanical replica

Come with 7 fake brass .32 Extra Short and a primer extractor

Mesures are same as real gun

Realistic markings

Fake groves on the barrel

The less:

Made of plastic so be carefull in using, be gentle

The weight due to the use of plastic is lighter than original (not so much important)

The lock system of the replica is the same as Turbiaux's model, not the Chicao Fire Arms Co.

Conclusion:

With 7mm caps, It's a perfect deal for a theatre or movie/serie screen use also than a private funny use.

As a collector and shooter with ancients weapons, i really love it.

It worth highly the price.

Thank you so much for shopping with us this time😊

We're absolutely thrilled to receive such a lovely review filled with love!

Since this product is not currently scheduled for re-production, we're delighted you were able to get your hands on it.

We will continue striving to provide excellent products and the best service possible so you'll keep choosing our store!

We sincerely look forward to your next visit😊

이번에 저희 매장을 이용해 주셔서 진심으로 감사드립니다😊

상품이 무사히 고객님께 전달되어 안심했습니다.

많은 사진을 찍어 주셔서 감사합니다😊

앞으로도 고객님께 우수한 제품과 최고의 서비스를 제공할 수 있도록 노력하겠습니다.

변함없는 애용 부탁드립니다!

고객님의 방문을 진심으로 기다리겠습니다.

何よりも、再生産品であるとしっかり示されている点がとても嬉しく感じました。

商品自体はマルイ製なので特に言及する必要は無いかと思います。

この度は当店をご利用いただき誠にありがとうございます😊

商品が無事にお手元に届き、お客様にご満足いただけて大変嬉しいです!

再生産品を選ばれたいお客様の気持ちとても分かります!最新の商品をお届けしておりますので安心してご利用くださいませ。

これからも引き続き当店を選んでいただけるよう、優れた製品と最高のサービス提供に努めてまいります! お客様のまたのご利用を心よりお待ちしております😊

さすがWALTHER社との提携をされているだけあり、緻密な再現に感激しています。ブラックとはまた一味違う美しいステンレスを楽しみたいと思います。

この度は当店をご利用いただき誠にありがとうございます😊

商品が無事にお手元に届き、お客様にご満足いただけて大変嬉しいです!

お客様のおっしゃる通り、こちらはワルサー社から商標の使用権を取得しているマルゼンだからこそできる再現性の高い製品となっています。

トリガー、ハンマーの機能や通常分解操作まで実銃同様に再現されたこのリアルさを是非お楽しみください。

これからも引き続き当店を選んでいただけるよう、優れた製品と最高のサービス提供に努めてまいります!

お客様のまたのご利用を心よりお待ちしております😊

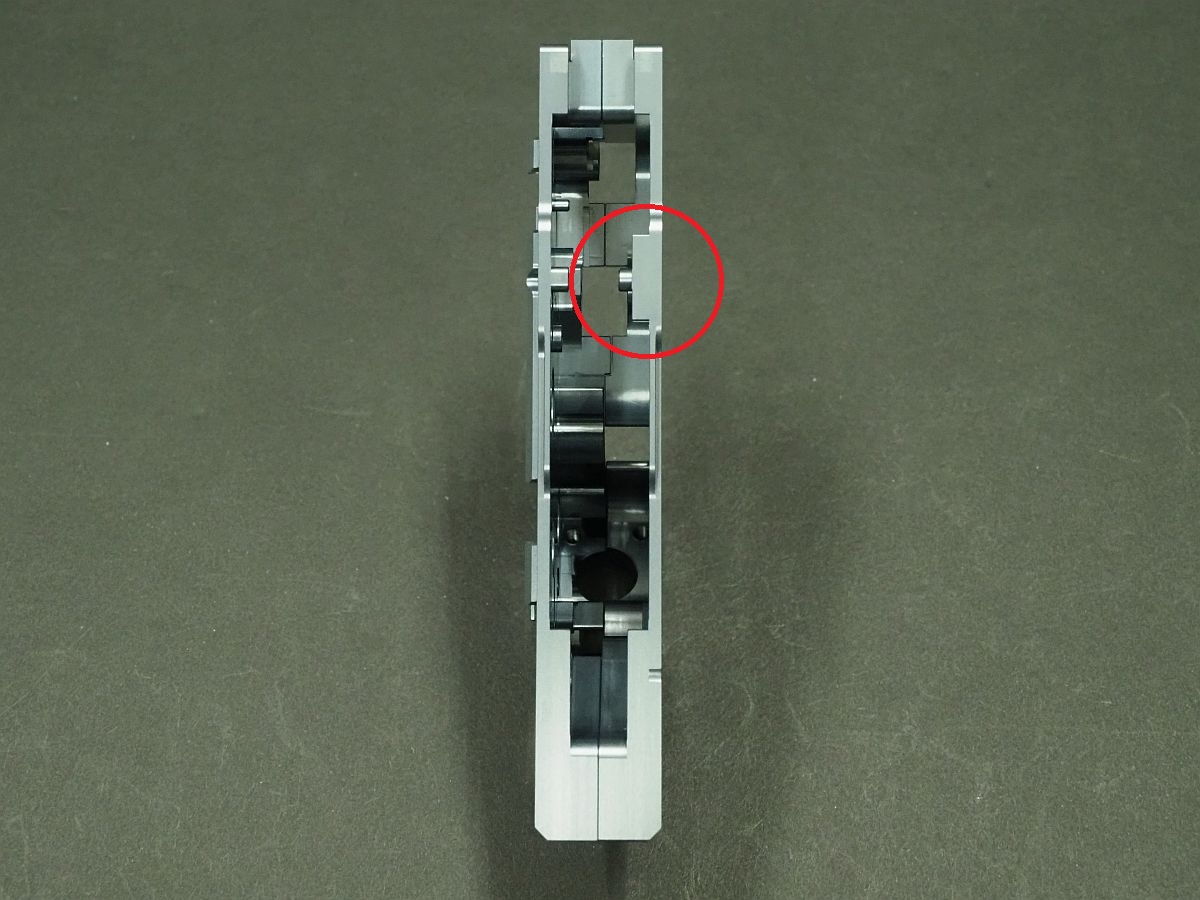

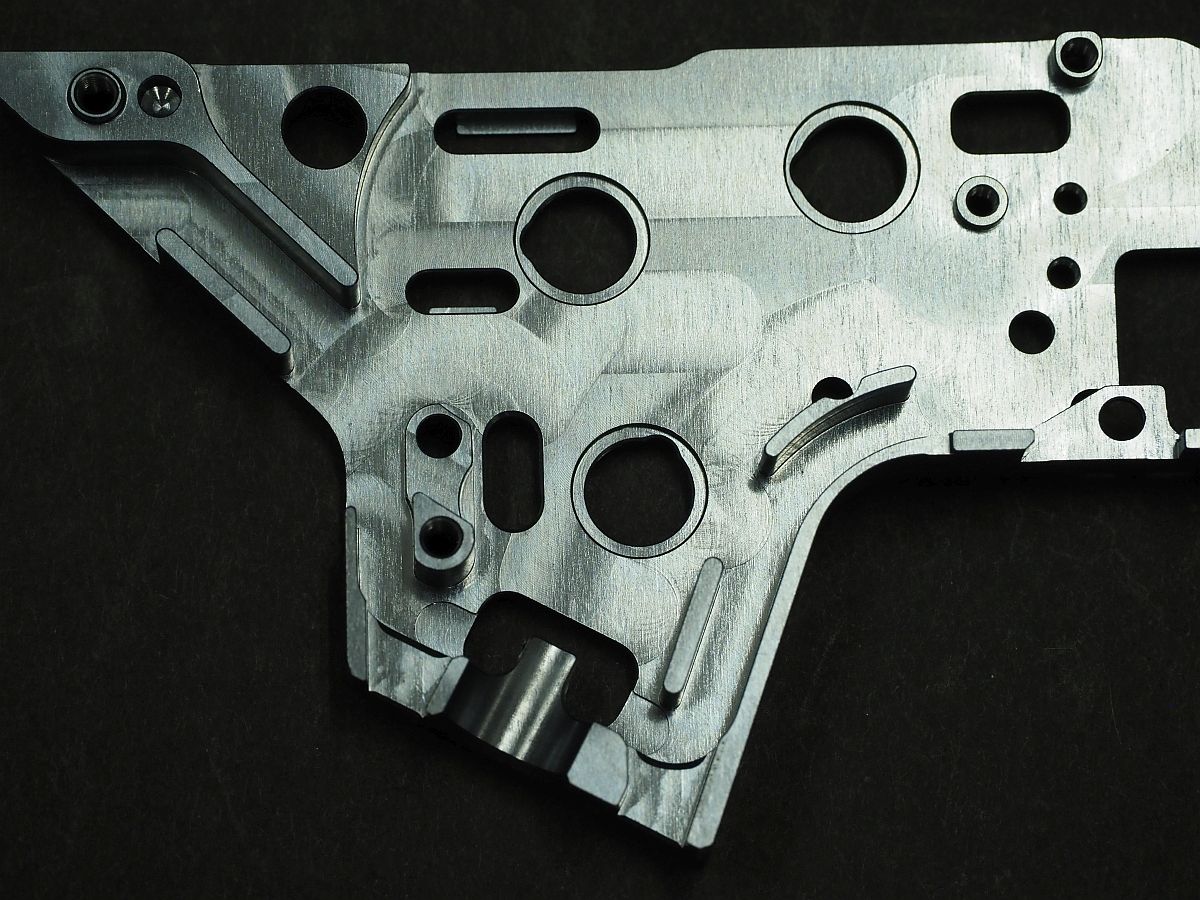

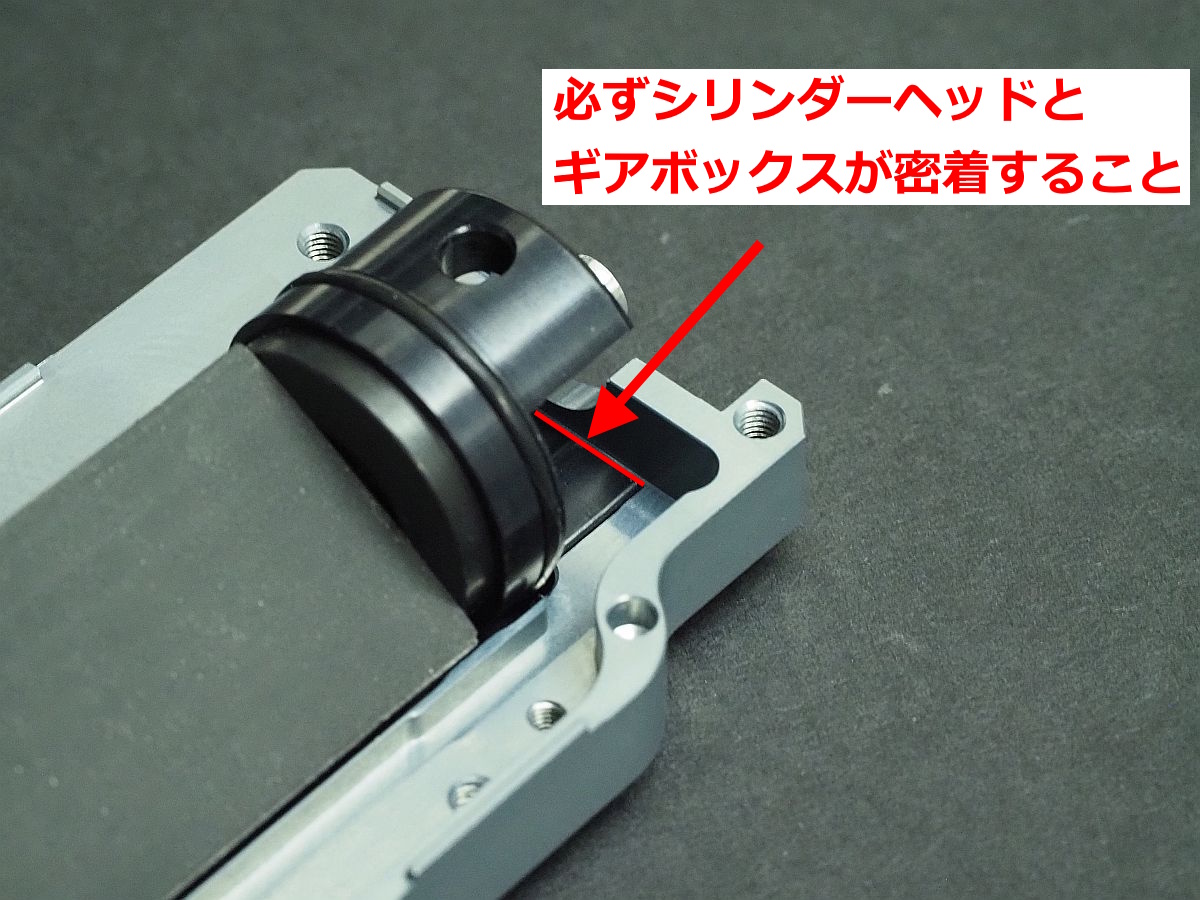

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_1024x1024.jpg?v=1750382227)

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_1_1024x1024.jpg?v=1750382227)

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_2_1024x1024.jpg?v=1750382227)

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_3_1024x1024.jpg?v=1750382227)

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_5_1024x1024.jpg?v=1750382227)

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_6_1024x1024.png?v=1750382227)

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_medium.jpg?v=1750382227)

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_1_medium.jpg?v=1750382227)

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_2_medium.jpg?v=1750382227)

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_3_medium.jpg?v=1750382227)

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_5_medium.jpg?v=1750382227)

![[RETRO ARMS] CNC Split Gearbox V2 (8mm) - QSC 2025](http://rock-et.jp/cdn/shop/files/RETRO-7066_6_medium.png?v=1750382227)